Comprehensive Guide to Selecting Fully Automatic Soybean Oil Press Machines for Efficient Small and Medium Oil Plants

2025-12-04

Tutorial Guide

Are you managing a small or medium oil plant and aiming to implement fully automatic soybean oil press machines but unsure where to start? This guide walks you through choosing the right machine based on your production capacity and raw material moisture content. Dive into detailed explanations of key components like filter screens, hydraulic systems, and temperature control modules, alongside essential installation, commissioning, and daily maintenance tips to avoid common pitfalls. Learn how energy-saving and eco-friendly designs can reduce long-term operational costs, helping you build an efficient and sustainable production line. A must-read practical handbook for newcomers seeking high-performance and green soybean oil extraction solutions.

Full-Automatic Soybean Oil Press Selection Guide for Small and Medium Oil Mills

Are you stepping into the world of automated soybean oil extraction and feeling overwhelmed by equipment choices? Selecting the right full-automatic soybean oil press is crucial for optimizing production, minimizing costs, and ensuring product quality. This guide is tailored for you — a small or medium oil mill owner or technical manager — looking to make informed decisions based on your specific needs.

Understanding Your Production Capacity Needs

Start by accurately estimating your daily throughput requirements. Presses range from compact units producing 100-300 kg/hour to industrial machines exceeding 1000 kg/hour. Overestimating capacity can cause underutilization and unnecessary capital expenses, while underestimating leads to production bottlenecks.

| Machine Model |

Ideal Capacity (kg/hr) |

Recommended Oil Mill Scale |

Water Content Tolerance (%) |

| Model A (Compact) |

100-300 |

Small |

8-12 |

| Model B (Standard) |

300-700 |

Medium |

6-10 |

| Model C (Industrial) |

700-1200+ |

Large |

5-8 |

Adapting to Raw Material Moisture Content

Your soybean's moisture level directly impacts filtration efficiency and overall output. For example, high water content (>12%) thickens the oil paste, increasing pressure on filter screens and leading to frequent clogging or equipment strain.

Choosing a model with adjustable or reinforced filter screen structures and versatile hydraulic pressure settings will help accommodate varying moisture content without compromising performance.

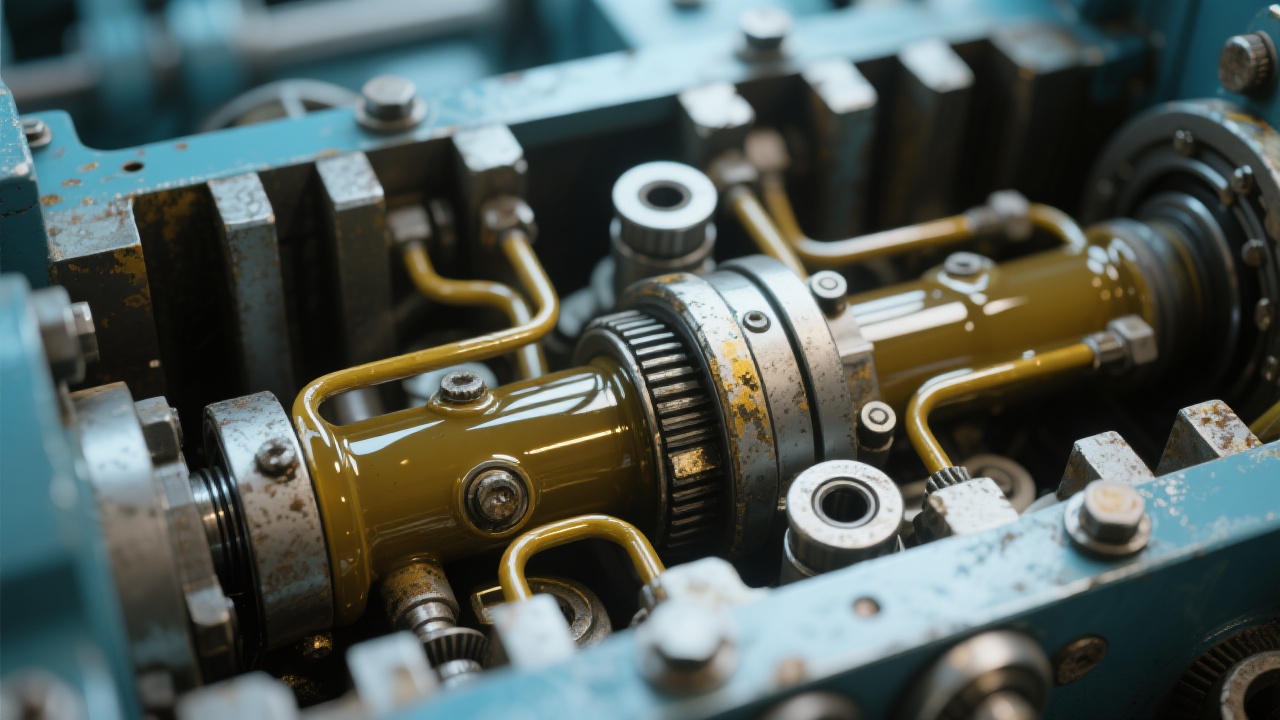

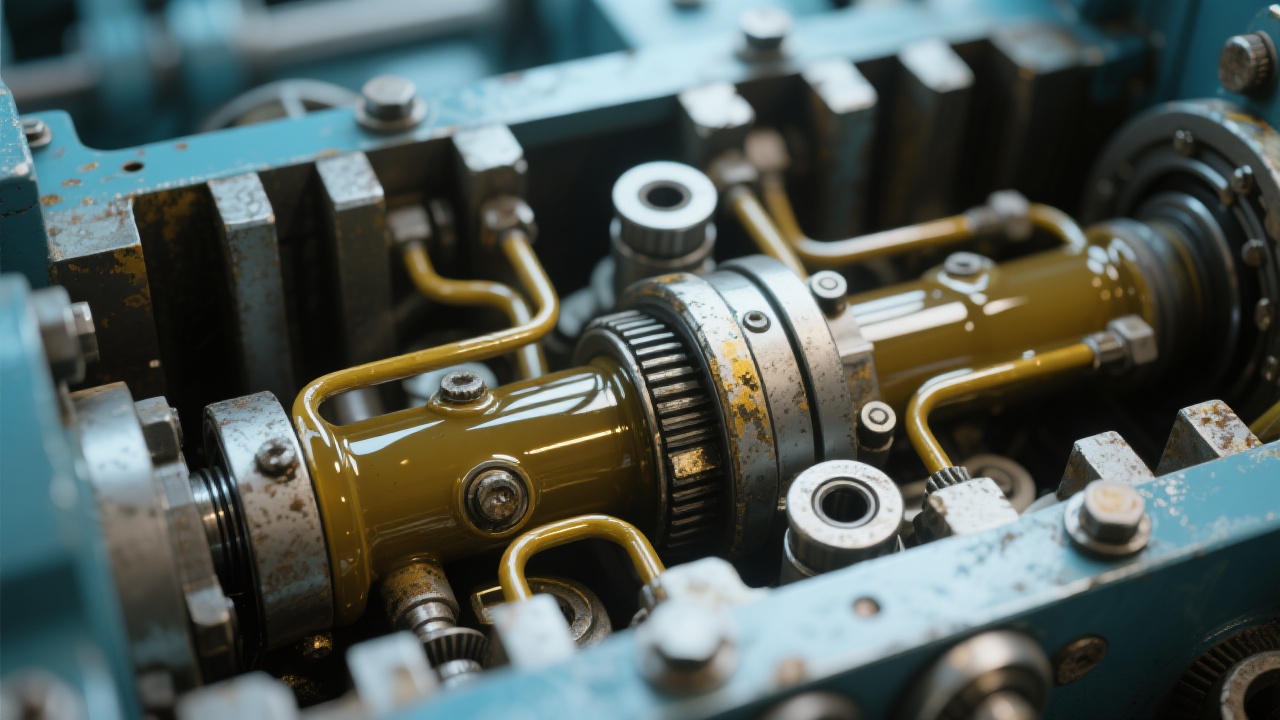

Key Components Breakdown: What Really Matters

Understanding the core parts of your press can greatly improve your operation skills and maintenance planning:

- Filter Screen Structure: Critical for separating crude oil from solid residues. Durable mesh with easy cleaning features reduces downtime.

- Hydraulic System: Provides the mechanical force to press soybeans. Features like pressure regulation and leak-proof seals enhance longevity.

- Temperature Control Module: Maintains optimal heating for the hot pressing process, improving oil yield and quality by carefully balancing temperature and press time.

Simulated Operational Scenarios: Adjusting to Material Variations

Imagine two scenarios:

- Low moisture content soybeans (5%): Your press runs with standard filter tension and hydraulic pressure set to medium levels, ensuring smooth extraction without overexerting components.

- High moisture content soybeans (12%): You increase hydraulic pressure and select a finer filtration setting to counter slower oil flow and prevent clogging, keeping output stable.

These adjustments are critical to avoid common pitfalls such as inefficient pressing, equipment damage, or excessive energy consumption.

Energy Efficiency and Environmental Impact: Why It Matters

Modern full-automatic soybean oil presses integrate energy-saving technologies such as variable frequency drives (VFDs), advanced heating insulation, and recyclable waste handling. This reduces operational costs by up to 15-20% annually compared to outdated machinery. Additionally, environmental compliance supports your brand's green transition.

Maintenance Tips to Maximize Machine Lifespan

Simple but regular maintenance keeps your press running flawlessly:

- Check and clean filter screens daily to prevent clogging.

- Inspect and lubricate hydraulic seals monthly.

- Monitor temperature control calibration after 1000 hours of operation.

- Run diagnostic checks quarterly to catch early signs of wear.

Thousands of clients across 120+ countries trust our equipment for reliable, year-round production backed by a 1-year worry-free warranty. Investing wisely now means smoother operations and lasting benefits.