In the global market of edible oil, especially for foreign - trade grain and oil processing enterprises, the quality of soybean oil refining plays a crucial role in stable shipments and customer satisfaction. This article will comprehensively explore the core technologies of degumming and deodorizing in soybean oil refining, aiming to help enterprises solve common quality pain - points.

When it comes to degumming, different types of degumming agents have their own characteristics. For example, phosphoric acid - based degumming agents are widely used due to their high efficiency in removing phospholipids. Controlling the pH value during the neutralization process is also vital. A proper pH range, usually between 6.5 and 7.5, can ensure the effectiveness of the neutralization reaction. In the deodorizing stage, the synergy between temperature and vacuum degree is significant. A temperature of around 230 - 260°C and a vacuum degree of 0.5 - 1 mbar can effectively remove unpleasant odors.

Many grain and oil processing enterprises often face challenges such as residual odors, unstable oil quality, and high energy consumption. To address the issue of residual odors, optimizing the deodorizing process parameters and using high - quality deodorizing equipment can be effective. For unstable oil quality, strict control of the entire refining process, from raw material selection to final product inspection, is necessary. Regarding high energy consumption, modern energy - saving technologies, such as heat recovery systems, can be adopted to reduce energy waste.

The integrated design of multiple processes in soybean oil refining can bring many benefits. By reducing manual intervention, the risk of human errors is minimized. For example, an automated control system can precisely adjust the process parameters, ensuring continuous and consistent production. This not only improves production efficiency but also enhances the overall quality of the refined oil.

One overseas factory applied our advanced degumming and deodorizing technology and equipment. After implementation, the product qualification rate increased to 99.2%, and customer complaints decreased by 40%. This case clearly demonstrates the effectiveness of our solutions in improving product quality and customer satisfaction.

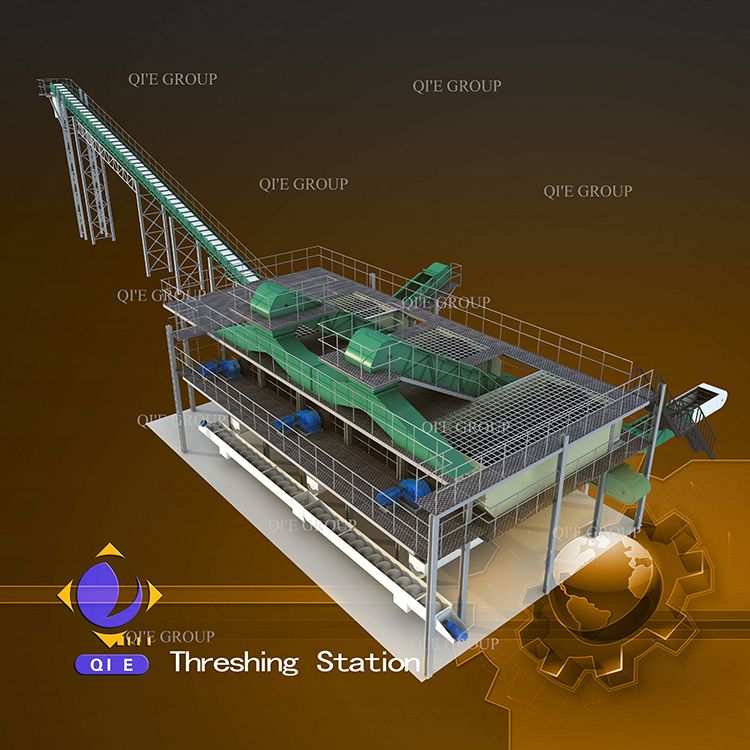

To help enterprises better understand the entire refining process, we provide a flowchart that shows the complete process from degumming to neutralization, bleaching, and deodorizing. Additionally, a parameter comparison table between traditional and modern processes is presented. This table clearly shows the advantages of modern technology in terms of efficiency, quality, and energy consumption.

| Process | Traditional Technology | Modern Technology |

|---|---|---|

| Degumming | Low efficiency, long time | High efficiency, short time |

| Deodorizing | Residual odor, high energy consumption | No odor, low energy consumption |

Our innovative solutions can bring significant improvements to your soybean oil refining process. If you are a foreign - trade grain and oil factory looking for a reliable and efficient refining system, welcome to learn about our fully automated degumming and deodorizing refining system designed specifically for you. Click here to explore more!