For producers in the animal feed industry, optimizing solvent recovery during oil extraction is no longer just a cost-saving strategy—it’s a core component of sustainable operations. According to recent data from the International Feed Industry Federation (IFIF), facilities using advanced solvent recycling systems report up to 25% lower solvent consumption and 18% reduced energy costs annually compared to traditional setups.

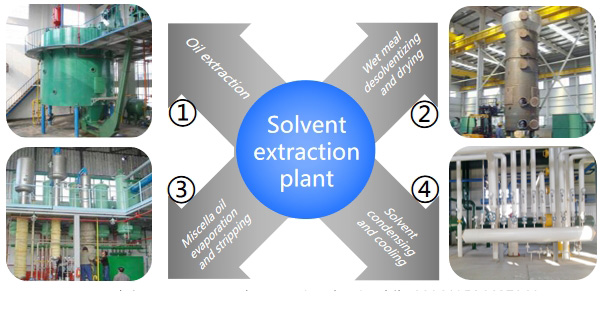

In soybean oil extraction for animal feed粕, solvents like hexane are essential—but inefficient use leads to both financial loss and environmental risk. A well-designed recovery system ensures that over 95% of solvent is reclaimed after extraction, minimizing waste and enhancing safety. This is particularly critical in regions with strict emissions regulations such as the EU and North America.

Key components—such as the countercurrent extractor (浸出塔), solvent condenser unit, and dehydration dryer—must be engineered for seamless integration. For example, one mid-sized feed mill in Brazil achieved a 97% solvent recovery rate by upgrading their condenser efficiency from 82% to 94%, resulting in an annual savings of approximately 12,000 liters of hexane.

Even with high-quality equipment, operators often face issues like incomplete solvent evaporation or inconsistent粕 moisture levels. In a case study from a feed plant in Thailand, poor heat distribution in the de-solventizer led to elevated residual solvent content (>0.5%)—a safety concern under ISO 22000 standards.

The fix? Implementing a multi-stage heating system with real-time temperature feedback. After retrofitting, the facility reduced solvent residue to below 0.2% and improved product consistency across batches—a key factor in winning repeat orders from international buyers.

Another frequent challenge is clogging in solvent condensers due to impurities. Regular maintenance protocols—including weekly cleaning cycles and automated filter monitoring—are now standard practice among top-tier processors. These steps not only extend equipment life but also reduce unplanned downtime by up to 40%.

Ultimately, integrating smart sensors, predictive analytics, and modular design into your solvent recovery setup transforms it from a passive utility into a strategic asset—one that supports compliance, reduces operational risk, and strengthens customer trust.

Download our free technical guide on designing efficient solvent recovery systems for animal feed粕 plants—packed with real-world benchmarks, maintenance checklists, and process flow diagrams.

Get the Free Technical Manual Now →