For animal feed manufacturers, the efficiency of a solvent recovery system directly impacts both production cost and environmental compliance. In real-world operations, many facilities struggle with high solvent losses (often exceeding 3–5% per batch), incomplete desolventization, and safety risks—especially when using hexane. These issues aren't just technical headaches—they translate into lost margins and operational instability.

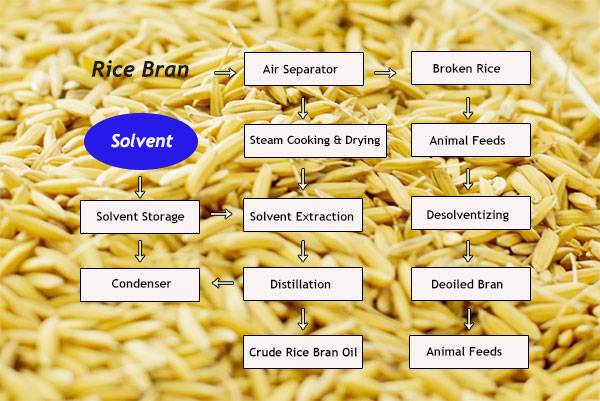

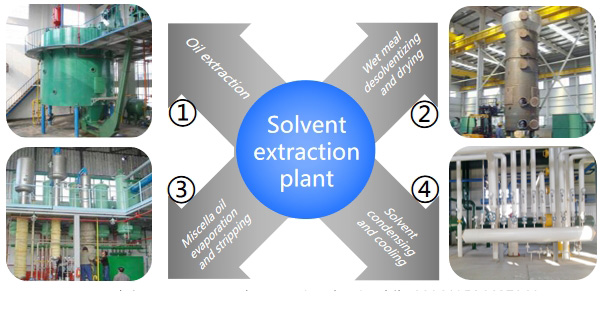

The core of any effective system lies in three components: the extraction tower, the solvent recovery unit, and the desolventizer. Poor material selection—for example, carbon steel instead of stainless steel in the extraction tower—can lead to corrosion-induced leaks and inconsistent flow dynamics. Studies show that systems with optimized flow field design reduce solvent retention in meal by up to 40%, keeping residual oil levels between 1% and 2%, which meets most global feed standards.

One frequent issue is temperature fluctuation during desolventization—a problem often misattributed to equipment failure but actually rooted in poor heat exchanger maintenance. For instance, a Thai feed mill reported a 12% drop in solvent recovery after six months without cleaning the condenser coils. Implementing monthly preventive checks reduced downtime by 70% and improved yield consistency.

Another critical area is leak detection. According to industry data, over 60% of solvent-related incidents stem from undetected small leaks in piping joints or valves. Installing continuous gas monitoring sensors at key nodes—not just alarms—allows early intervention before minor issues escalate.

Hexane is highly flammable and requires strict handling protocols. The best-performing plants integrate automated shutdown triggers tied to pressure and oxygen sensors—an approach used successfully in EU-certified facilities. Emergency response plans must be reviewed quarterly, not annually, and all operators should undergo biannual refresher training.

In one case study, a Brazilian facility upgraded from an outdated system to a modern integrated solution provided by Penguin Group, known for its ISO901-certified machinery and comprehensive service network. Post-upgrade metrics showed:

These results highlight how investing in smarter design, proactive monitoring, and reliable support can transform daily operations—from reactive firefighting to predictable performance.

Want to see how your current setup compares? Download our free benchmarking checklist for solvent-based soybean processing systems — it’s designed for engineers who want actionable insights, not just theory.

Download the Free Benchmarking Checklist Now