In the production of animal feed meal, high solvent loss and incomplete desolvation are common pain points faced by engineers and production managers. These issues not only increase production costs but also have a negative impact on environmental protection. This article aims to provide practical solutions to these problems through in - depth analysis and real - case studies.

Solvent loss and incomplete desolvation are significant challenges in the animal feed meal production process. High solvent loss not only leads to increased raw material costs but also poses potential environmental risks. Incomplete desolvation can result in higher oil content in the feed meal, which may affect the quality and safety of the final product. For example, in some traditional production processes, the solvent loss rate can reach up to 5%, and the oil content in the feed meal may exceed 5%, far from the ideal production standards.

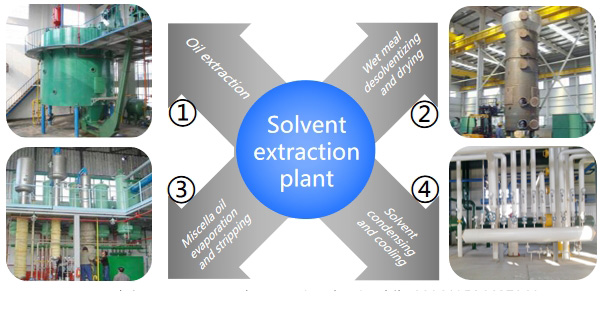

The high - efficiency solvent recovery system mainly consists of leaching towers, evaporators, condensers, dryers, and other components. Each component plays a crucial role in the solvent recovery process. The leaching tower is responsible for extracting oil from soybeans using solvents, while the evaporator separates the solvent from the miscella. The condenser then condenses the vaporized solvent for reuse, and the dryer removes the remaining solvent in the feed meal.

These components work together to ensure high - efficiency oil extraction and solvent utilization. For instance, the leaching tower and the evaporator need to maintain a proper material flow rate and temperature to ensure that the oil is extracted completely and the solvent is separated effectively. The condenser and the dryer need to be well - coordinated to ensure that the solvent is recovered to the maximum extent and the feed meal meets the quality requirements. Through scientific design and operation, the solvent recovery rate can reach over 95%, and the oil content in the feed meal can be controlled below 2%.

In a real - world soybean oil production plant, improper operation of the solvent recovery system led to a solvent loss rate of about 3% and a feed meal oil content of about 3.5%. After in - depth analysis, it was found that the problem was mainly due to the unreasonable setting of the operating parameters of the evaporator and the condenser. By adjusting the temperature, pressure, and flow rate of these components and strengthening the daily maintenance of the equipment, the solvent loss rate was reduced to less than 1%, and the feed meal oil content was reduced to about 1.5%.

A reasonable process layout can ensure the smooth flow of materials and energy in the production process, reducing unnecessary energy consumption and material losses. Automation control can improve the accuracy and stability of the production process, ensuring the consistency of product quality. Regular maintenance of equipment can prevent equipment failures and extend the service life of the equipment, ensuring the long - term stable operation of the production process.

In summary, optimizing the solvent recovery system in animal feed meal production can achieve the triple values of energy - saving, safety compliance, and stable output. By implementing the solutions provided in this article, engineers and production managers can effectively solve the problems of solvent loss and incomplete desolvation, improving the economic and environmental benefits of the enterprise.

Download the Solvent Recovery System Design Manual or Book a Technical Consultation Now!