In the highly competitive edible oil industry, refining processes such as degumming and deodorization are critical to ensuring superior oil quality and consumer acceptance. This case study explores how an export-oriented soybean oil refinery implemented targeted optimization strategies in its degumming and deodorization stages—resulting in substantial improvements in oil purity and flavor stability.

The degumming step primarily removes phospholipids and impurities that adversely affect oil clarity and shelf life. The choice and dose of degumming agents directly impact not only gum removal efficiency but also downstream deodorization effectiveness.

In this case, the refinery transitioned from conventional acid degumming to a well-controlled enzymatic degumming process, applying phospholipase at precisely dosed levels (0.03% w/w relative to oil). Kinetic studies informed the optimization of the neutralization stage where the residual free fatty acids (FFA) are titrated with caustic soda. Maintaining the reaction temperature at 70°C ± 2°C and a controlled pH of 6.8 to 7.0 minimized over-neutralization and soap stock formation—key factors enhancing subsequent deodorization.

| Parameter | Before Optimization | After Optimization | Improvement |

|---|---|---|---|

| Degumming Agent Dosage | 0.05% Acid | 0.03% Enzymatic | 40% reduction |

| Neutralization pH | 7.3 - 7.5 | 6.8 - 7.0 | Improved precision |

| Free Fatty Acid Content (FFA)% | 0.12% | 0.08% | 33% reduction |

Prior to optimization, the refinery faced recurring issues of persistent off-flavors and inconsistent oil quality, particularly linked to residual phosphatides and incomplete deodorization. These problems not only affected consumer acceptance but also increased production scrap and reprocessing costs.

Targeted strategies entailed adjusting steam stripping conditions in deodorization—specifically increasing stripping steam flow rates by 15% and maintaining vacuum pressure consistently below 5 mmHg. This reduced volatile off-flavor compounds such as hexanal and trans-2-heptenal by over 25%, verified through gas chromatography analysis.

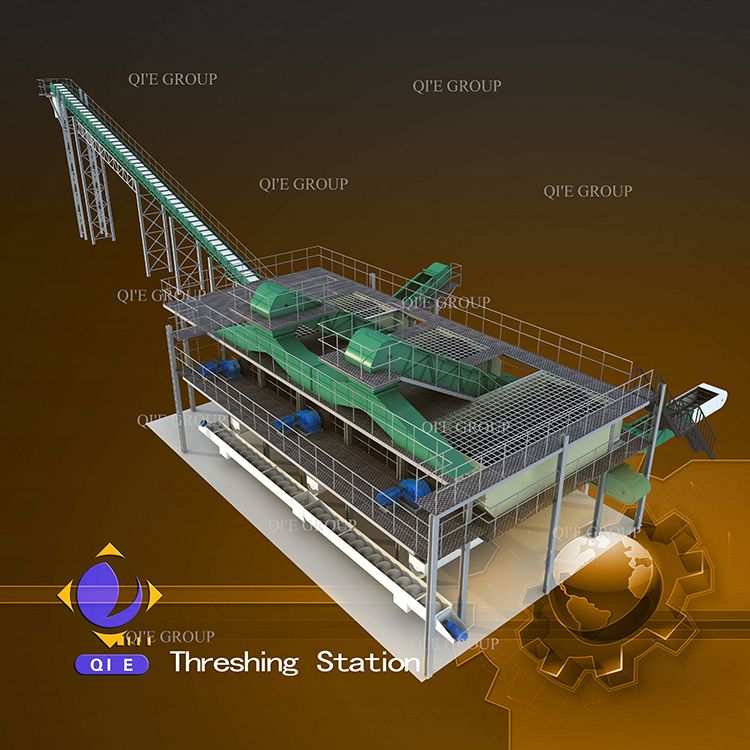

Another core highlight was the integration of a modular refining system. This design streamlined the degumming and deodorization units into a cohesive workflow with automated parameter controls and real-time monitoring.

The automation decreased manual intervention by 40%, reducing human error in critical steps such as chemical dosing and temperature regulation. Staff found the intuitive human-machine interface (HMI) reduced training time and improved process consistency — key benefits in scaling high quality output for global markets.

Performance metrics from a key overseas client revealed that post-upgrade, oil yield increased by approximately 5%, while residual impurities dropped below 10 ppm—a threshold critical for premium oil grades. Moreover, energy consumption in the deodorization section decreased by 8%, reflecting enhanced thermal efficiency.

| Metric | Pre-Upgrade | Post-Upgrade | Improvement |

|---|---|---|---|

| Oil Yield | 91.2% | 95.8% | +4.6% |

| Impurities (ppm) | 25 | 8 | -68% |

| Energy Use (kWh/ton) | 120 | 110 | -8.3% |

These quantifiable enhancements underscore how precision control and process integration can elevate both operational efficiency and final product quality—factors crucial for export competitiveness.

For grain and oil processors aiming to replicate these successes, adopting advanced refining solutions tailored to precise degumming and deodorization control is essential. Our complete line of one-stop edible oil refining equipment integrates modular design with smart automation, enabling consistent high-quality output while optimizing production costs.

Explore detailed technical specifications and customizable configurations on our equipment page to discover how your facility can achieve new benchmarks in soybean oil quality and export readiness.