In the realm of edible oil processing, the refining of soybean oil stands as a critical step in ensuring high - quality products. This article delves deep into the degumming and deodorizing technologies of the soybean oil refining equipment independently developed by Penguin Group, aiming to assist edible oil processing enterprises in enhancing production efficiency and product competitiveness.

The choice of degumming agent is fundamental to the degumming process. Different degumming agents have distinct chemical properties and performance characteristics. For instance, phosphoric acid is a commonly used degumming agent. It can effectively bind with non - hydratable phospholipids in soybean oil, converting them into hydratable forms for easier removal. Citric acid, on the other hand, can chelate metal ions in the oil, which helps in improving the stability of the oil during subsequent processing.

When selecting a degumming agent, several factors need to be considered. Firstly, the acidity and reactivity of the degumming agent should match the quality of the crude soybean oil. Secondly, the cost - effectiveness is also crucial. Generally, phosphoric acid costs around $0.5 - $1 per kilogram, while citric acid is slightly more expensive, at about $1 - $1.5 per kilogram. The dosage of the degumming agent also varies according to the type of oil and the degumming agent used. Typically, the dosage of phosphoric acid ranges from 0.1% - 0.5% of the oil weight, and for citric acid, it is around 0.05% - 0.2%.

The neutralization reaction is a key step in the degumming process. It involves the reaction between the free fatty acids in the oil and the alkaline solution. The efficiency of this reaction directly affects the degumming efficiency and the quality of the refined oil. According to reaction kinetics, factors such as temperature, reaction time, and the concentration of the alkaline solution have a significant impact on the reaction rate.

The optimal temperature for the neutralization reaction is usually between 50 - 60°C. At this temperature range, the reaction rate is relatively high, and at the same time, it can prevent the hydrolysis of triglycerides. The reaction time is generally controlled within 20 - 30 minutes. If the reaction time is too short, the reaction will be incomplete; if it is too long, it may lead to the formation of soaps and reduce the oil yield. The concentration of the alkaline solution also needs to be carefully adjusted. A common concentration of sodium hydroxide solution used in the neutralization reaction is 10% - 20%.

The deodorizing process is essential for removing unpleasant odors from soybean oil. Modern deodorizing technologies mainly include steam distillation and vacuum deodorization. The key control parameters in the deodorizing process include temperature, vacuum degree, and steam flow rate.

The deodorizing temperature is usually maintained at 200 - 240°C. At this high temperature, the volatile odor - causing substances in the oil can be effectively removed. The vacuum degree should be controlled at 2 - 4 mmHg to ensure the smooth progress of the distillation process. The steam flow rate is typically 2% - 5% of the oil weight per hour. By precisely controlling these parameters, the quality of the deodorized oil can be significantly improved.

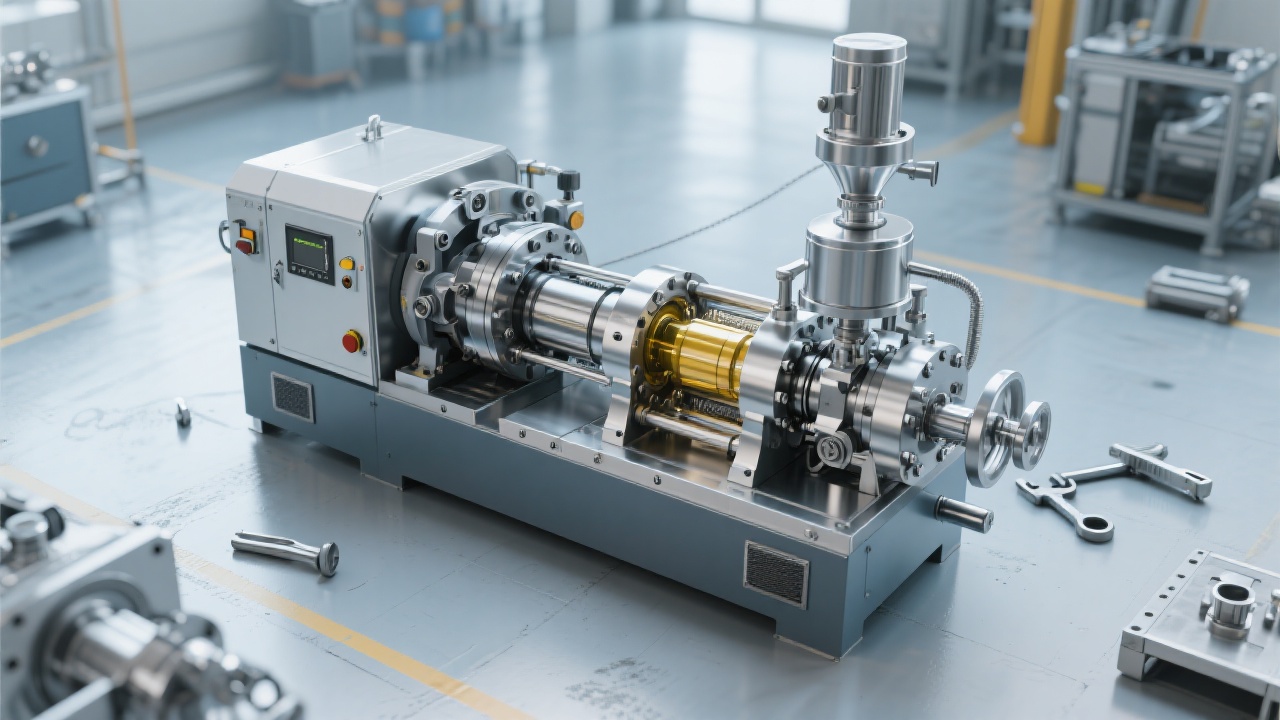

Penguin Group's soybean oil refining equipment adopts a multi - process integrated design concept. This type of equipment integrates degumming, neutralization, deodorizing, and other processes into one unit, which has many advantages. Firstly, it improves the operation convenience. Operators can complete multiple processes through a single control system, reducing the complexity of operation. Secondly, it enhances the stability of production capacity. The integrated design can better coordinate the different processes, ensuring a more stable and efficient production process.

In addition, the automation of the equipment is another significant advantage. With advanced sensors and control systems, the equipment can automatically adjust parameters such as temperature, flow rate, and pressure according to the production requirements, which not only improves the production efficiency but also reduces the labor intensity.

In practical production, various problems may occur. For example, during the degumming process, if the degumming efficiency is low, it may be due to improper selection of the degumming agent or incorrect control of the reaction conditions. By analyzing the specific situation, adjusting the type and dosage of the degumming agent, and optimizing the reaction temperature and time, the problem can be effectively solved.

Another common problem is the presence of residual odors in the deodorized oil. This may be caused by insufficient deodorizing temperature or improper vacuum degree. By carefully checking and adjusting these parameters, the odor problem can be resolved.

In conclusion, Penguin Group's soybean oil refining equipment, with its advanced degumming and deodorizing technologies, provides a reliable solution for the edible oil processing industry. If you are looking to upgrade your production equipment and improve product quality, don't miss out on Penguin Group's high - performance soybean oil refining equipment. Click here to learn more!