When it comes to animal feed粕 (by-product) processing, the efficiency of solvent recovery in soybean oil extraction systems directly impacts both profitability and environmental compliance. According to industry benchmarks from the International Association of Oilseed Processors (IAOP), a well-designed system can reduce solvent loss by up to 40%, translating into annual savings of $50,000–$100,000 per facility—depending on throughput.

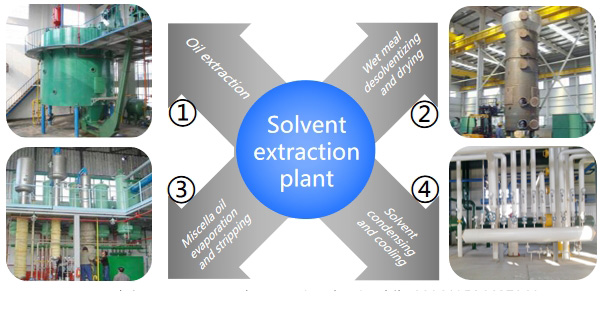

The core of any high-performance solvent recovery setup lies in three integrated components: the extraction tower, the solvent recovery unit, and the drying/de-solventizing equipment. These aren’t standalone machines—they must work in harmony.

For example, a leading Chinese feed mill reported a 27% drop in solvent consumption after optimizing their evaporator-condenser sequence—a change that also reduced fire hazards by improving vapor pressure control. This was achieved not through expensive upgrades but by reconfiguring the flow path between the extraction chamber and the recovery condenser based on real-time temperature data.

Many operators overlook how layout affects heat transfer efficiency. A poorly arranged system forces the solvent vapor to travel longer distances before condensing—increasing energy use and risk of leakage. Studies show that placing the condenser within 3 meters of the extraction tower reduces energy costs by an average of 15%. Also, installing automatic pressure sensors at each stage allows early detection of leaks—critical for facilities handling hexane, which has a lower flammability threshold than many assume.

In one case study from Brazil, a feed producer saw a 30% improvement in batch consistency after implementing a modular design approach where each process step could be independently monitored and adjusted using IoT-enabled controllers. The result? Fewer rejected batches and smoother operations during peak season.

Operators often misdiagnose low recovery rates as equipment failure when they’re actually due to poor maintenance practices. For instance, clogged condenser tubes can reduce efficiency by over 35%. Regular cleaning every 6 months—not just once a year—is essential. Another frequent issue is improper drying temperatures; too high leads to protein degradation in the meal, while too low leaves residual solvent above safe limits (typically >100 ppm).

Our team helped a European feed manufacturer solve this exact problem by introducing a closed-loop monitoring system that alerts operators when solvent levels exceed thresholds—cutting down on manual checks and increasing operator confidence in daily operations.

Want more? Download our free technical guide: "Solvent Recovery Best Practices in Feed Processing – A Step-by-Step Manual"

Plus, book a 30-minute consultation with our engineering experts to review your current setup and get personalized recommendations.