In the competitive landscape of small and medium-sized oil mills, achieving a high soybean oil extraction rate has always been a challenging goal. Traditional pressing processes often suffer from low oil yield and high impurity levels. Let's delve into the root causes of these issues to understand the necessity of 'instant filtration'.

One of the main reasons for low oil yield in traditional methods is the lack of immediate filtration. As the oil is extracted, it remains in contact with the residues and impurities for an extended period, leading to oxidation and increased oil retention in the residues. This not only reduces the net oil output but also affects the quality of the final product.

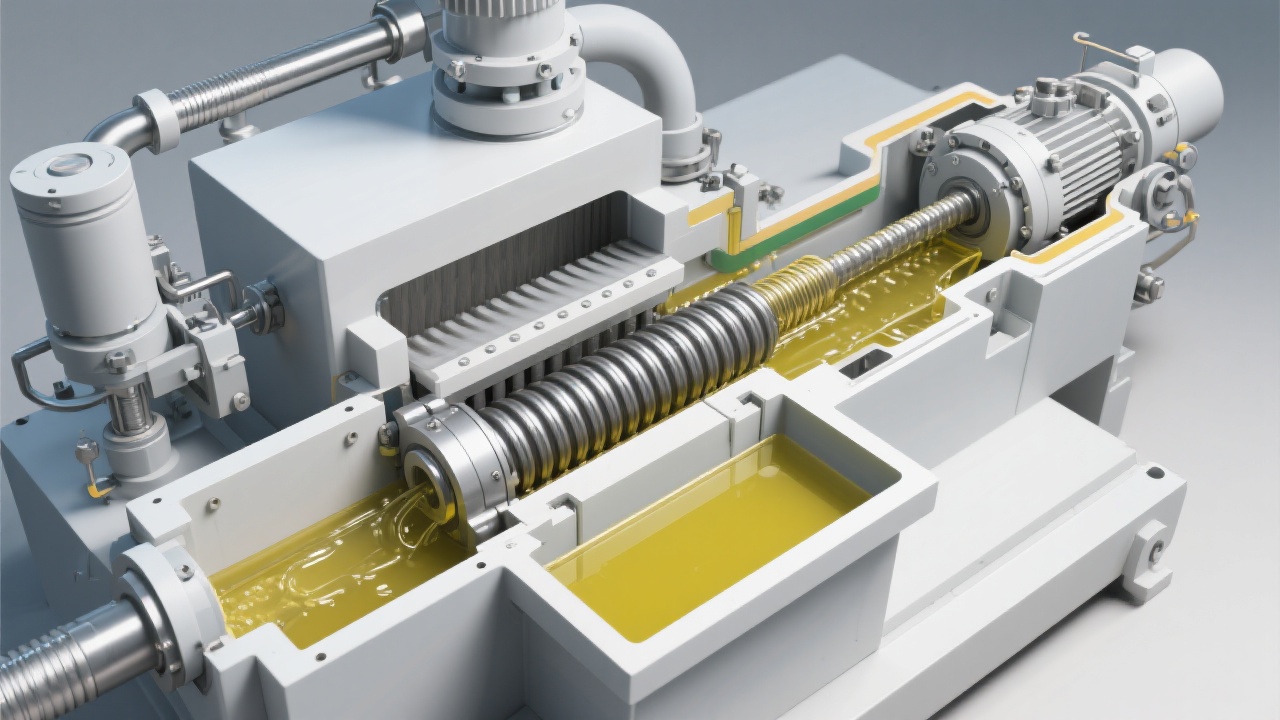

The integrated automatic soybean oil press with an oil filtration system offers a revolutionary solution. In both hot-pressing and cold-pressing scenarios, this system works in sync with the pressing process, enabling immediate filtration.

In hot-pressing, the high temperature helps to break down the oil cells more effectively, but it also increases the risk of oxidation. The integrated filtration system quickly separates the oil from the hot residues, reducing the oxidation time. This can lead to an average increase in oil yield of about 10 - 15% compared to traditional hot-pressing methods. In cold-pressing, the system ensures that the oil is filtered while maintaining its natural nutrients and flavor. It can reduce the residual oil rate in the cake to less than 5%, significantly improving the overall extraction efficiency.

To fully leverage the benefits of the automatic filtration press, proper parameter adjustment is crucial. For example, the moisture content of the soybeans should be carefully controlled. Generally, a moisture content of around 10 - 12% is optimal for both hot and cold pressing. If the moisture is too high, it can lead to lower oil yield and more impurities in the oil. If it's too low, the beans may not be pressed effectively.

Temperature control is another key factor. In hot-pressing, the temperature should be maintained between 100 - 120°C to ensure efficient oil extraction without excessive oxidation. In cold-pressing, the temperature should be kept below 60°C to preserve the quality of the oil. Many operators make the mistake of neglecting these parameters, which can result in sub - optimal performance.

From equipment configuration to operation management, a comprehensive process optimization can bring long - term benefits. When configuring the equipment, ensure that the press is properly sized for your production volume. A well - matched press can improve the overall efficiency and reduce energy consumption.

In operation management, establish a regular maintenance schedule for the press and the filtration system. This can prevent breakdowns and ensure continuous production. Additionally, train your staff on the correct operation and parameter adjustment to maximize the performance of the equipment.

The automatic filtration press is designed with energy - saving and environmental - friendly features. It consumes less energy compared to traditional presses, which can lead to significant cost savings in the long run. Moreover, the reduced oil retention in the residues means less waste, which is in line with the sustainable development needs of small and medium - sized enterprises.

By adopting this advanced technology, your enterprise can not only increase the oil yield but also save labor costs and ensure stable production. If you have any questions or need more information about how to optimize your soybean oil production process, please leave a message below. Click here to learn more about how our automatic filtration press can transform your business and help you achieve maximum value from every batch of soybeans.